Prof. Pedro Da Costa

KAUST, Saudi Arabia

Biography

Dr. Pedro Da Costa is an Assistant Professor of the Materials Science and Engineering Program at the King Abdullah University of Science and Technology (KAUST) and Principal Investigator of the Laboratory for Carbon Nanostructures (KAUST).

Previously, he held an Adjunct Assistant Professor position at the University of Aveiro (UA), Portugal, and co-founded a start-up, Graphene Crystal, Saudi Arabia. Before that, he was a Junior Research Group Leader at UA while also collaborating has an Alexander von Humboldt Fellow with the IFW-Dresden, Germany. Dr. Costa worked as a post-doctoral research associate at the National Institute for Materials Science (NIMS), Japan, and at the Department of Materials Science and Metallurgy of the University of Cambridge, United Kingdom (UK). His graduate studies were carried out under the supervision of Prof. Malcolm L. H. Green FRS, at the Inorganic Chemistry Laboratory, University of Oxford, UK. He is a member of various acknowledged scientific societies such as the Royal Society of Chemistry (RSC), the Royal Microscopical Society and the Materials Research Society. He is an active committee member of the RSC Interest Group - Chemical Nanoscience and Nanotechnology. Dr. Costa has co-authored numerous scientific papers and communications and he is a regular reviewer for major scientific journals in matters related to electron microscopy and carbon nanostructures. He has received several awards such as the Japan Carbon Award for Young Researchers and an Alexander von Humboldt Fellowship for Experienced Researchers.

Presently, Dr. Costa's research interests focus on carbon nanostructures, from synthesis to applications, and electron microscopy. He is engaged in understanding how to optimise the use of carbon-based materials in the fields of energy storage/conversion, gas uptake and civil engineering. Besides this, he also investigates metrology of carbon materials.

Title

Thin films of graphite grown on Ni foils by chemical vapor deposition

Abstract

Graphite thin films (GTF) are used as heat-sinks in electronic devices such as mobile phones. Generally, the thickness of these films is in the order of tens of micrometers due to production methods being based on the pyrolysis and graphitization of polymers [1]. As devices scale down, it is important to ensure that thermal management solutions continue to be available which, furthermore, conform to market regulations. Thus, over the past decade, there has been renewed interest in the use of chemical vapor deposition (CVD) to grow sub-micrometer GTF with high structural quality and low surface roughness.

Since the CVD process relies on the thermal dissociation of hydrocarbons onto transition metal substrates, it is important to tailor the catalytic foil to the type of graphite aimed. Due to the relatively high solubility and diffusivity of C into Ni, this metal is commonly preferred for the growth of GTF (as opposed to Cu, the most popular substrate for the growth of single-layer graphene by CVD). To present, there is still little understanding of how to control the production of GTF from Ni foils and if it is possible to achieve wafer-scaled films with less than 100 nm that can be handled without cracking.

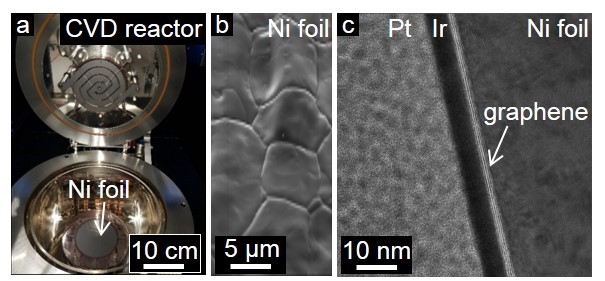

In this communication, we will show our recent efforts to produce wafer-scale high-quality GTF with thickness below 100 nm (Fig. 1). Detailed structural analysis of the catalyst-graphite interface and the study of the reactor's parameters permitted valuable insight to the mechanism of GTF formation. Remarkably, regions with just a few layers of graphene were identified (Fig. 1c). Despite this, these films were robust and could be dissociated from the metal foil without the use of a polymer support. After transfer, they retained the expected properties of GTF, added to visible light transparency.

Figure 1: Thermal CVD growth of GTF on Ni foils. (a) Photo of the CVD reactor chamber with a 4" Si wafer where a Ni metal foil was placed; (b) Scanning electron micrograph of the Ni surface with µm-sized grains; (c) Transmission electron micrograph of a post-growth Ni foil, seen in cross-section, where regions with a very thin layer of graphite (graphene) are present. The Pt and Ir originate from the microscopical lamella preparation (by focused ion beam).

References

[1] M. Murakami, K. Watanabe, S. Yoshimura, High-quality pyrographite films, Appl. Phys. Lett., 48 (23), 1594-1596 (1986).

All sessions by Prof. Pedro Da Costa

Session theme: Developing carbon-based industry

KAUST, Saudi Arabia