Prof. Suresh Advani

University of Delaware, USA

Biography

Suresh G. Advani is George W. Laird Professor of Mechanical Engineering and Associate Director, Center for Composite Materials at the University of Delaware. He received his Ph. D from University of Illinois at Urbana-Champaign in 1987. His research interests are in rheology; fluid mechanics and heat transfer as applied to composite processing and alternate energy sources such as fuel cells and hydrogen storage. Advani has published over 350 journal papers and delivered over 200 invited lectures. He is the lead author of a text on Process Modeling in Composite Manufacturing Processes. Professor Advani is a Fellow of American Society of Mechanical Engineers and is the North American Editor for the journal Composites Part A: Applied Science and Manufacturing. Professor Advani recently received the Outstanding Researcher Award for 2015 from American Society of Composites and the Educator of the Year award from Society of Plastic Engineers. Professor Advani is also the creator of Liquid Mold Filling Software called LIMS which is used by many industries and academic institutions to advance the manufacturing science of composites.

Title

Emerging Role of Process Models and Simulations in Composites Manufacturing

Abstract

This talk will highlight the ever increasing benefits of process modeling in Composite Manufacturing processes. First, the use of science base approach of materials processing, which integrates material parameters with transport phenomena at various scales during manufacturing to create multi-physics models will be discussed. Next the importance of implementing these models in fast and open architecture simulations that can be seamlessly interfaced with optimization, functional design and process control tools to improve the yield of the process despite the variability in the incoming materials and process parameters will be demonstrated. The use of such simulations in transportation, wind and energy storage applications will be presented. Automation can be introduced with tailored equipment designs that rely on sensors and simulations interfaced with actuators to address variability and disturbances in the process. Examples where this has been demonstrated on a laboratory scale will be presented for Liquid Molding processes such as Resin Transfer Molding, Vacuum Assisted Resin Transfer Molding and Compression Resin Transfer Molding. This approach naturally lends itself to Digital Twins and Industry 4.0 Manufacturing.

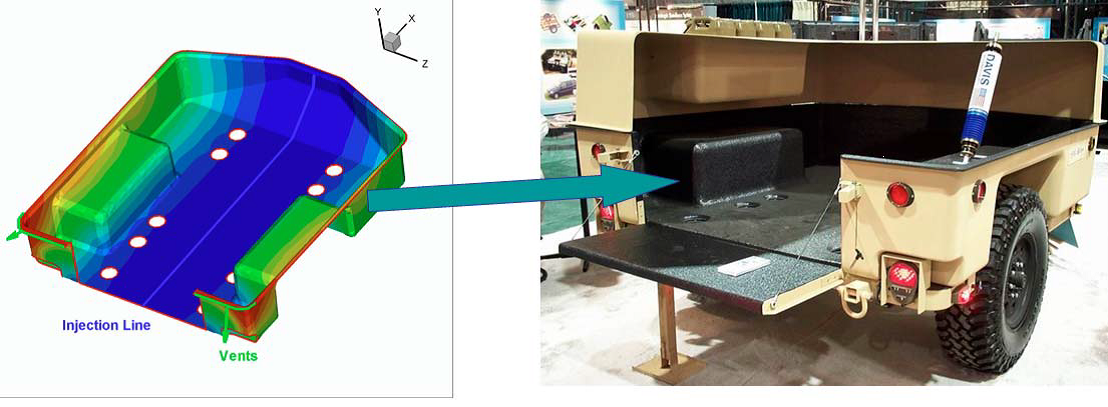

Figure 1: Mold Filling Simulation of a Tractor Trailer Bed through a center line gate injection with last regions to fill at the corners. Such simulations can be integrated in Digital Twin Designs in the Future for Industry 4.0 Manufacturing

All sessions by Prof. Suresh Advani

Session theme: Advancing processing through models and data

University of Delaware, USA