Prof. Gerard Fernando

University of Birmingham, UK

Biography

Professor Gerard Fernando was appointed to the Chair of Polymer Engineering in 2005 at the School of Metallurgy and Materials, University of Birmingham, UK. Prior to this, he was a Reader and Lecturer at the Royal Military College of Science, Shrivenham, UK and Brunel University, London, UK, respectively. His primary research interest is in the design and deployment of optical fibre-based sensor systems for: (i) chemical process monitoring; and (ii) structural integrity assessment of fibre reinforced composites.

In addition to developing a unique multi-measurand optical fibre sensor for engineering materials, he has developed the following techniques for fibre reinforced composites (patents secured or applied): (i) clean filament winding and environmentally friendly pultrusion; (ii) fibre spreading; (iii) production of vertically-aligned short-fibre core material for sandwich composites; and (iv) the production of highly-aligned organic fibres as a continuous process via electro-spinning – which includes the production of aligned lignin fibres.

Title

Chemical Process Monitoring and Structural Integrity Assessment using Optical Fibre Sensors

Abstract

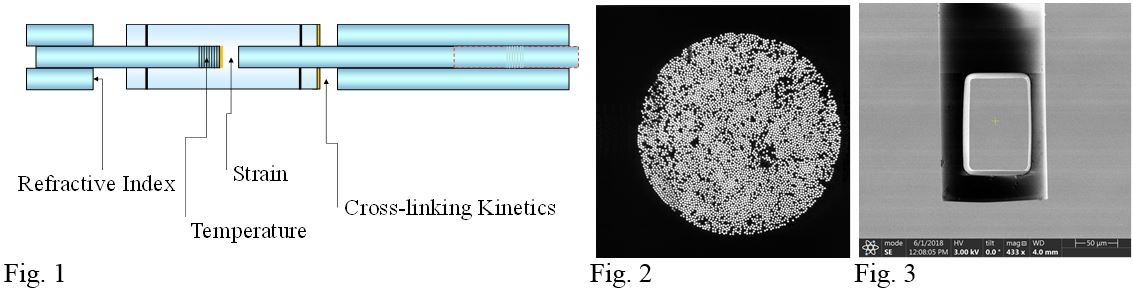

Significant advances have been made in recent years, on the design and deployment of optical fibre sensors for chemical processes monitoring and structural integrity assessment of engineering materials. However, the majority of these devices tend to impart information on one measurand. It is proposed that in order to assess the chemical, thermal and mechanical integrity of materials, information on two or more parameters is required. In this presentation, two case studies are considered. The first case study describes the design and demonstration of a multi-measurand fibre optic sensor system that is capable of imparting information on strain, temperature, cross-linking kinetics and refractive index. A schematic illustration of the multi-measurand sensor for use with thermosetting resins is shown in Figure 1. Recent developments on cure monitoring and damage detection using the reinforcing E-glass fibres and small-diameter optical fibres will be considered (Figure 2). Techniques for the production of intrinsic Fabry-Perot cavities in conventional optical fibres (Figure 3), for sensing applications, will be presented. The second case study discusses the integration of optical fibre sensors into a differential scanning calorimeter. Here, data are acquired simultaneously on the thermal, spectral and refractive index during the processing of a thermosetting resin. It will be demonstrated that establishing correlation between the various analytical techniques can facilitate the development of low-cost optical fibre sensors for thermosetting/thermoplastic resins and composites.

Figure 1: Schematic illustration of the multi-measurand sensor [1]. Figure 2: Self-sensing composite using small-diameter optical fibres [2, 3]. Figure 3: Intrinsic Fabry-Perot cavity in a conventional optical fibre.

References

[1] AK, Nair, VR Machavaram, RS Mahendran, SD Pandita, C Paget, C Barrow and GF Fernando, "Process monitoring of fibre reinforced composites using a multi-measurand fibre-optic sensor", Sensors and Actuators B: Chemical, Volume 212, 93-106, (2015).

[2] L Wang, A Tomlin, SD Pandita, BD Gupta, SA Malik, M Hudson, PT Curtis and GF Fernando, "In-situ monitoring of cross-linking reactions using E-glass fibres and evanescent wave spectroscopy", Sensors and Actuators B: Chemical 236, 358-366, (2016).

[3] SA Malik, L Wang, PT Curtis, GF Fernando, "Self-sensing composites: In-situ detection of fibre fracture", Sensors 16 (5), 615, (2016).

All sessions by Prof. Gerard Fernando

Session theme: Advancing processing through models and data

University of Birmingham, UK