4B: The Future of Composites with Graphene Nanopetals: Scalable Deposition of Graphene Nanopetals on Carbon Fiber

Abstract

Graphene nanopetals are vertically-aligned carbon nanostructures materials that can be deposited on carbon fiber. Several studies showed that graphene nanopetals decrease the interfacial thermal and electrical resistances of composites, improve the interfacial strength of composites, and enhance the sensitivity and selectivity of biosensors. Here, a large-scale roll-to-roll plasma chemical vapor deposition (CVD) system was implemented to mass-produce graphene nanopetals on carbon fiber [1]. Microscale and macroscale characterization techniques were used to optimize the growth process using a sequential design of experiment model. Results show the improved density of the carbon nanostructures with increased production time. Furthermore, a heat transfer model was developed to quantify the influence of temperature distribution of carbon fiber in the roll-to-roll graphene deposition. The model was validated with in situ temperature measurements of carbon fiber in the plasma region using optical emission spectroscopy. This work aims to expand the production of graphene-coated carbon fiber for future applications of composites in energy, transportation, and sensing.

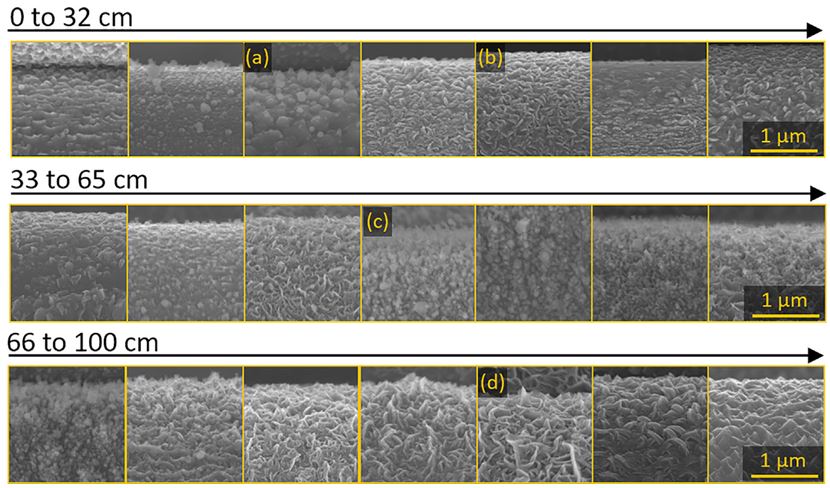

Figure 1: SEM images of graphitic petals along the 1-m long carbon fiber tow. Different morphologies exist depending on the production time, including a) separate graphene nanopetals, b) small-area growth of graphene nanopetals, c) unstructured graphene nanopetals, and d) extensive deposition of graphene nanopetals. The figure is extracted from [1].

References

[1] K. R. Saviers, M. A. Alrefae, and T. S. Fisher, Roll-to-Roll Production of Graphitic Petals on Carbon Fiber Tow, Advanced Engineering Materials, v.20(8), 1800004 (2018).

Speakers

Prof. Majed Alrefae

Royal Commission Yanbu, Saudi Arabia