Keynote 2: Thin-ply hybrid composites with pseudo-ductile response in tension, compression and bending

Abstract

Composite materials have excellent specific strength and stiffness, but a major drawback is their lack of ductility. This paper shows how thin-ply hybrid laminates can be created that give a more gradual failure, drawing on the work of the High Performance Ductile Composite Technology programme (HiPerDuCT) between the University of Bristol and Imperial College.

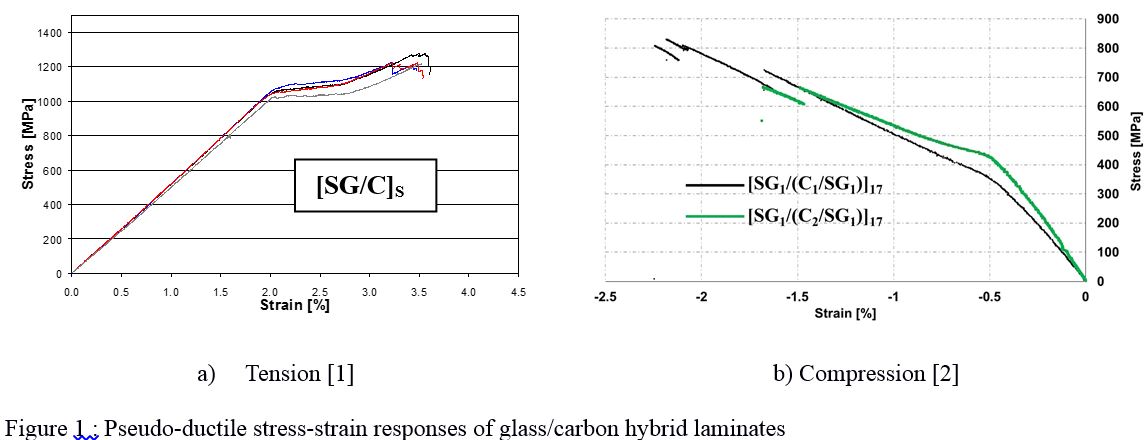

Thin plies can suppress matrix cracking and delamination and prevent premature failure. Thin-ply hybrid composites, for example of glass and carbon, or different grades of carbon fibres, can produce stable fibre fracture in the low strain to failure material without delamination occurring. This ply fragmentation creates a plateau on the tension stress-strain curve as progressive fragmentation occurs with load transfer onto the higher strain material, Fig. 1a. Nonlinear behavior due to ply fragmentation can also occur in compression by deformation on angled compression cracks and localized delamination, Fig. 1b. The pseudo-ductility allows load redistribution around stress concentrations, making the material less notch sensitive and potentially more damage tolerant. This paper describes the pseudo-ductile behaviour of thin-ply hybrids in tension, compression and bending and shows how they can produce a more gradual failure response.

Figure 1 : Pseudo-ductile stress-strain responses of glass/carbon hybrid laminates

References

[1] G. Czél, M. Jalalvand, M. R. Wisnom, Design and characterization of advanced pseudo-ductile unidirectional thin-ply carbon/epoxy-glass/epoxy hybrid composites, Composite Structures, 143, 362–370 (2016)

[2] P. Suwarta, G. Czél, M. Fotouhi, J. Rycerz, M. R. Wisnom, Pseudo-ductility of Unidirectional Thin Ply Hybrid Composites in Longitudinal Compression, ASC 33rd Annu. Tech. Conf., Seattle, Sept. 2018.

Speakers

Prof. Michael Wisnom

University of Bristol, UK